- recuperator burners

- control devices for burner technology

- radiant tubes for heating industrial furnaces

- electric heating elements as well as

- a customer-specific switch cabinet construction.

Our products are sold in over 35 countries around the globe and are used in heat treatment plants and facilities for the heating of metals and non-ferrous metals. We also have our own subsidiaries in China, India, and in the US.

Since our founding in 1992, our company headquarters have been in Oederan/Saxony, and we manufacture our products in Germany, according to the individual specifications of our customers. For burner experiments and quality checks, we have an internal, state-of-the-art technical center with 3 furnaces, test benches, and measuring technology. Our quality management system is DIN EN ISO 9001 certified, and we continuously work on improving and advancing it.

Our close cooperation with foundries, companies in metal processing and metal working, but also with assembly and installation businesses allows us to offer high flexibility and short project lead times to our customers. Burner parts and other components are manufactured and supplied for the most part regional companies. These components are then assembled into functional burners and control units at our facility in Oederan and installed in new installations or reconstructions in industrial furnace systems.

Our NOXMAT service team knows all there is to know about the heating systems of gas-fired and electrically heated industrial furnaces.

We consult and support our customers with great expertise and extensive service offers in the construction and optimization of heating elements for industrial thermal processing plants as well as maintenance and modernization in order to increase energy efficiency.

Industrial burners

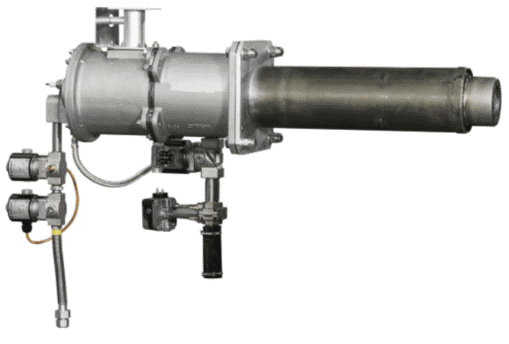

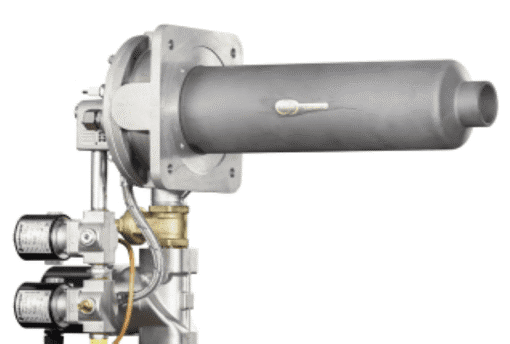

RHGBS series "ETAMAT"

The high efficient NOXMAT recuperator burner ETAMAT sets new standards in energy savings with a combustion efficiency of up to 90%. Available in a power range from 15 to 35 kW, burners of this series achieve the highest possible heat recovery thanks to a special recuperator.

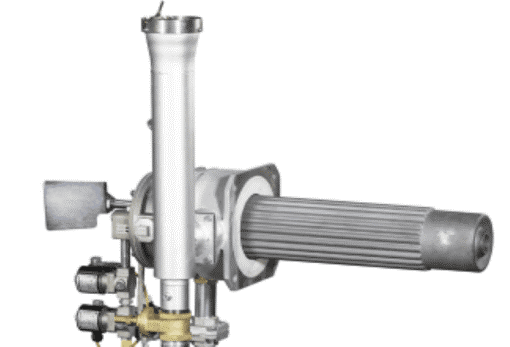

K-RHGB-RN series "REMAT"

The NOXMAT retrofit recuperator burner REMAT is characterized by its easy installation in existing systems, but also by higher energy efficiency, significantly reduced wear and less expensive maintenance.

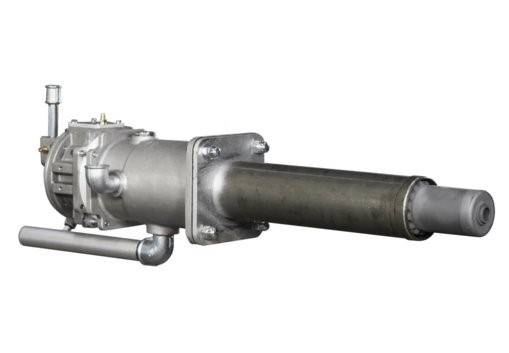

RHGB series

The classic NOXMAT recuperator burners (RHGB) improve energy efficiency through the internal preheating of the combustion air. They are suitable for the direct and indirect heating of industrial furnaces up to an application temperature of 1150 ° C and are available in a wide range of outputs from 7 to 250 kW.

K-RHGB series

The ceramic NOXMAT recuperative burners of the K-RHGB series improve energy efficiency through the internal preheating of the combustion air. They are suitable for the direct and indirect heating of industrial furnaces up to a maximum application temperature of 1300 ° C and are available in a wide range of outputs from 9 to 250 kW.

K-RHGBE series

The single-stage recuperator burners (K-RHGBE) are an inexpensive alternative to the classic recuperator burner. Suitable for direct and indirect heating of industrial furnaces up to an application temperature of 1,300 ° C and available in a wide range of outputs from 9 to 100 kW.

HGBE series

The NOXMAT cold air burners of the HGBE series are available in a power range from 9 to 160 kW. They are suitable for cold and preheated air operation (up to 400 ° C air preheating). The large flame pulse, which is immediately present when the burner is started, improves the temperature uniformity in the thermoprocessing system..

WIEDEMANN series

NOXMAT continues the products of the burner manufacturer Wiedemann. These are tubular recuperative burners for non-ferrous metallurgy, cold air burners and flat flame burners.

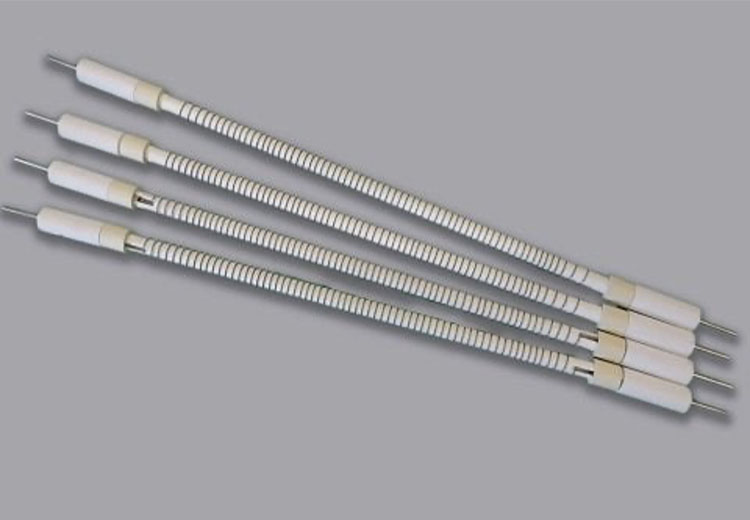

Electric Heating Elements for Industrial Furnaces

As an alternative to our proven recuperative burner systems for gas-fired industrial furnaces, we also offer a wide range of heating elements for electrically heated furnaces.

Our own project planning department supports you in the selection and dimensioning of the optimal heating variant for your production process. We are the ideal partner thanks to our many years of experience with indirect, radiant tube heating systems. Our own service team supports you with maintenance, replacement or optimization of your heating systems.

From standardized products to customer-specific solutions to highly specialized new developments: We have the right product for your requirements.

Bayonet Heating Elements (rod type)

Rod Heating Coils (spiral type)

Bayonet Heating Elements (ribbon type)

Cage Heating Elements

Meander Heating Elements

Special Heating Elements

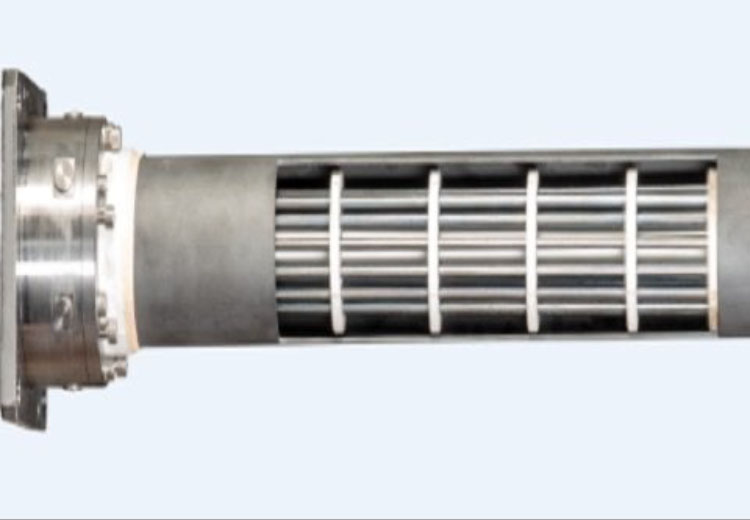

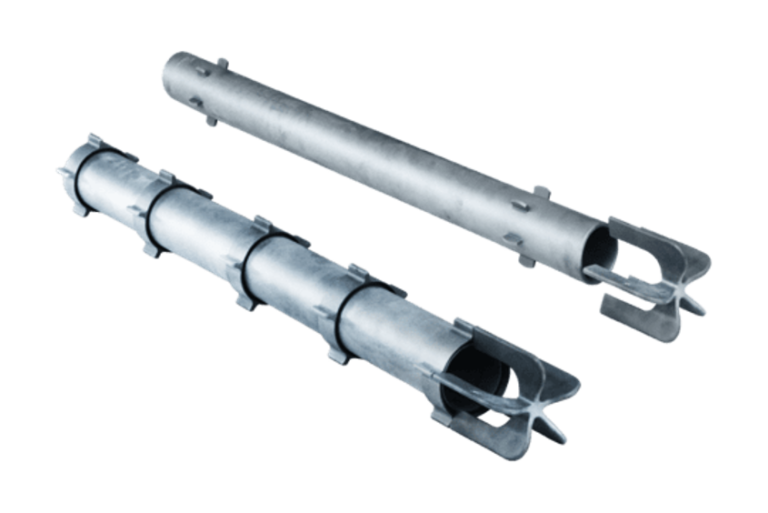

Radiant tubes

The NOXMAT radiant tubes are the perfect addition to our highly efficient burners for indirect heating of industrial furnaces. They are available in a wide range of materials and dimensions, are easy to install and maintain, and are all leak-tested.

Straight radiant tubes in ceramic design

Straight radiant tubes in ceramic design for the indirect heating of industrial furnaces in the high temperature range, suitable for horizontal and vertical installation, can be combined with burners in ceramic and steel design and also suitable for electrical heating systems.

Straight radiant tubes in steel design

Straight radiant tubes in steel design for the indirect heating of industrial furnaces, suitable for horizontal and vertical installation, can be combined with burners in ceramic and steel designs.

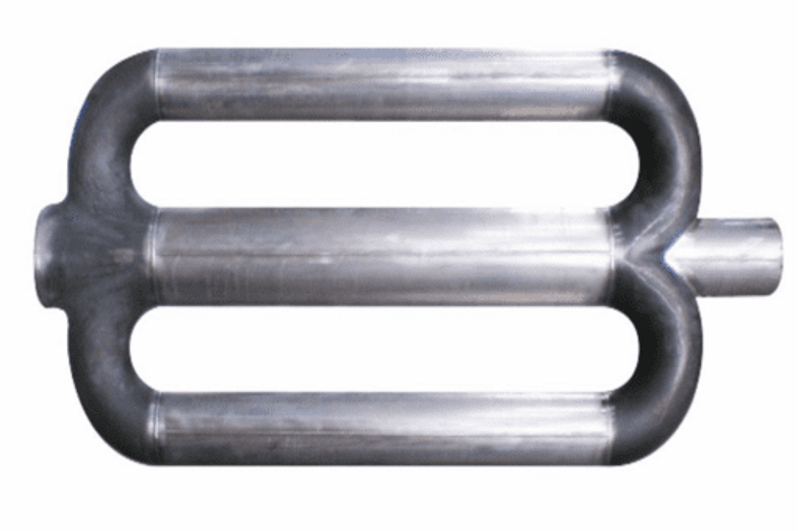

Radiant tubes in special design

The wide selection of NOXMAT radiant tubes in various dimensions and diverse designs (U, P, double-P or W shape) covers all areas of application for the indirect heating of industrial furnaces.

Our experts will be happy to advise you on the correct dimensioning and material selection for your specific application.

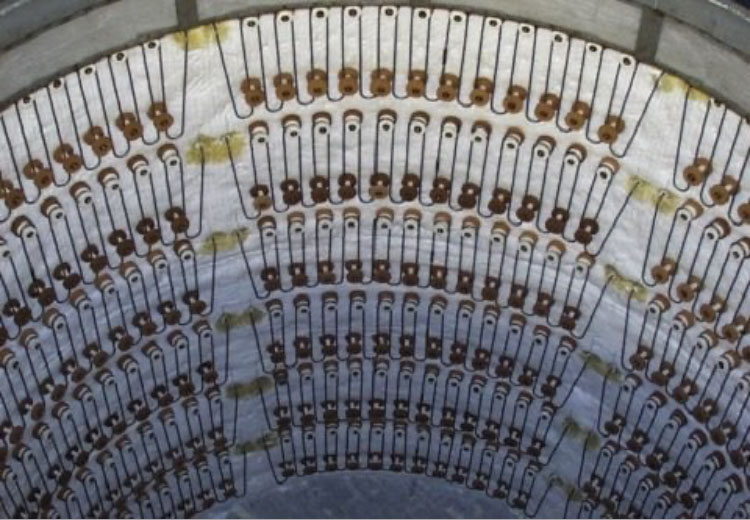

Accessories

NOXMAT delivers:

- flame tubes made of heat-resistant steel or ceramics, segmented or in one-piece

- spacers centering rings made of high-quality ceramic to complement the NOXMAT radiant tubes

- flange brackets for NOXMAT radiant tubes

System components

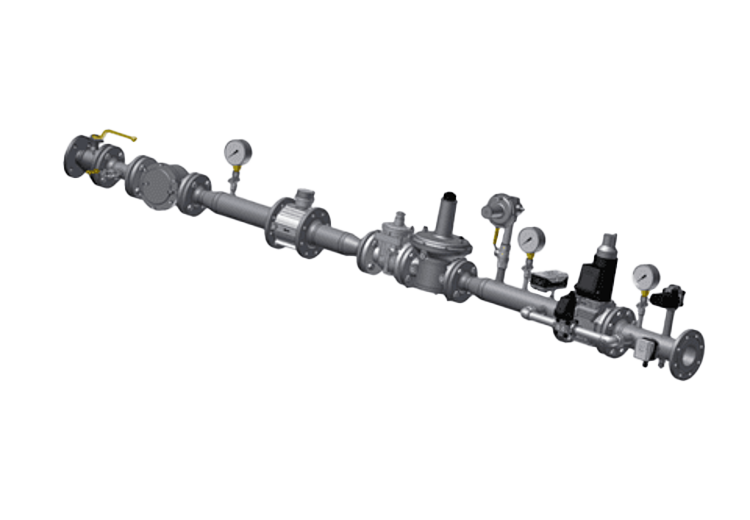

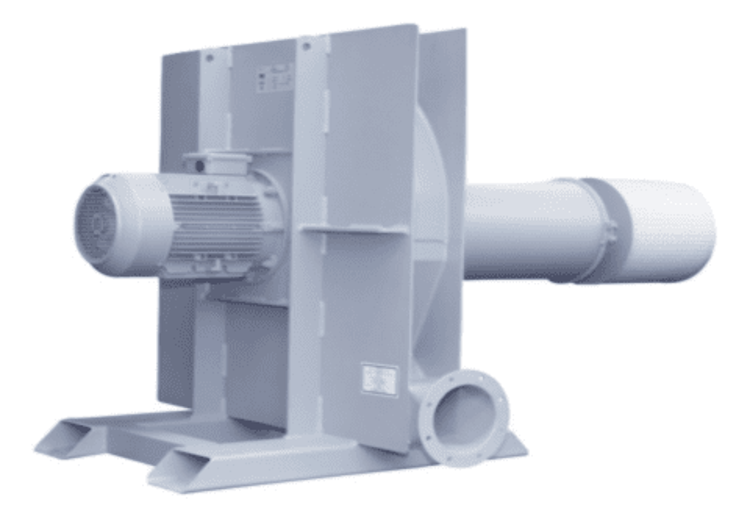

In addition to our high efficient burners, we also offer the associated equipment that is precisely tailored to the optimal operation of the NOXMAT burners.

These include the gas pressure control, measuring and safety lines, combustion air fans, a variety of burner controls (BCU) and other central components such as measuring orifices, UV probes, various gas and air valve designs and all other accessories for the optimal operation of your thermoprocessing system.

Gas-pressure control

measuring orifices

Measuring orifices

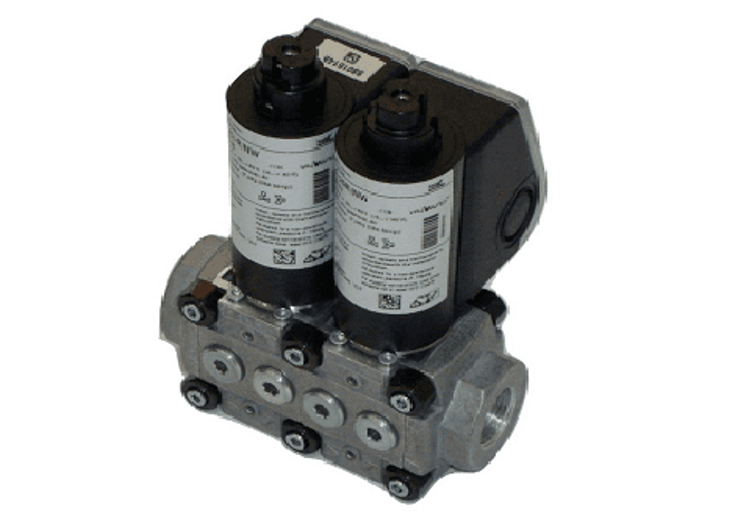

Burner controls (BCU)

Gas and air valves

Pressure switches

UV sensors

Spare parts

Company Headquarters

Galtex spol. s r. o.

Ulica 8.mája 16

821 06 Bratislava

Slovakia